High lead tin bronze sleeve

Category: Copper sleeve for mining machinery

Description:

Hotline:086-373-6615898

Characteristics and Applications

High lead tin bronze sleeve, wear-resistant self-lubricating copper sleeve, environmental protection recyclable copper sleeve. This product is based on excellent electrolytic copper as the base, matching the tin ingots and lead ingots according to the national standard ratio. In the absence of lubricants and water lubricants, it exhibits excellent sliding and self lubricating properties. Under the load of high speed rotation and rolling motion, the impact resistance is 50MPa, showing excellent flexibility. It is the first choice for high-speed running machinery.

Detailed parameters

Product Name: high lead copper bushing

Material brand: ZQPbD15-8

Casting mode: centrifugal casting

Product category: medium copper sleeve, straight bushing

Comprehensive introduction

Material name: Casting 15-8 high lead tin bronze

Brand name: ZCuPb15Sn8

Standard: GB/T 1176-1987

Chemical composition:

Copper Cu: the rest

Tin Sn:7.0 ~ 9

Zinc Zn: less than 2 (not included in the sum of impurities)

Lead Pb:13.0 ~ 17

Phosphorus P: less than 0.10 (impurity)

Nickel Ni: less than 2 (not included in the sum of impurities)

Aluminum Al: less than 0.01 (impurity)

Iron Fe: less than 0.25 (impurity)

Manganese Mn: less than 0.2 (impurity)

Silicon Si: less than 0.01 (impurity)

Antimony Sb: less than 0.5 (impurity)

Sulfur S: less than 0.10 (impurity)

Note: the total amount of impurities is less than 1

Mechanical properties:

Tensile strength sigma B (MPa): > 200

Yield strength (MPa): > 100

Elongation of delta 5 (%): > 6

Hardness: > 635HB (reference value)

Heat treatment specification: heating temperature is 1200~1250 C; pouring temperature is 1150~1200 C.

Casting method: centrifugal metal casting

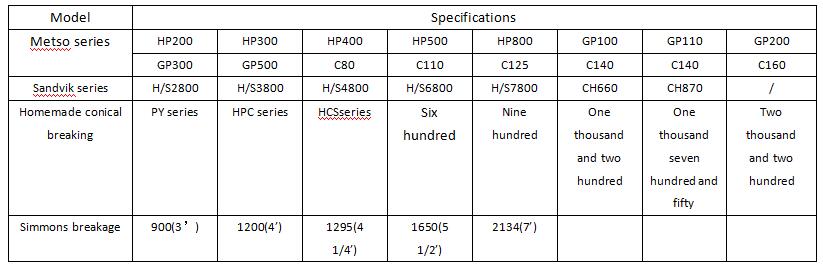

Field of application

Application of crusher type and specification field